Rubber Tracks for Compact Track Loaders

Find product for your machine:

Skid Steer Tracks

McLaren Industries is the leading rubber track manufacturer offering the most extensive line of tread patterns. With more than 25 years of experience producing the most durable skid steer rubber tracks, McLaren offers a product that meets the needs of any environment or application. Being the top producer of skid loader tracks in the United States, you can count on our years of expertise to deliver you a product you can count on.

No matter which you choose, all of our tracks feature our exclusive SpoolRite Belting Technology™. This technology features a single continuous steel cable belting with no natural weak spots. Our skid steer tracks comprise multiple product lines and tread patterns and sizes. There is something for every fleet and every job, whether it's construction work in rocky soil, soft mud, slick clay, or extreme weather conditions like snow.

Determining which of our skid steer tracks is right for you depends primarily on the environment you are working in with your machine. McLaren offers multiple rubber track product lines to match your needs, options include NextGenTM, Maximizer plus, and Maximizer series.

Benefits of McLaren Skid Steer Tracks

McLaren Industries' skid steer tracks offer several working advantages.

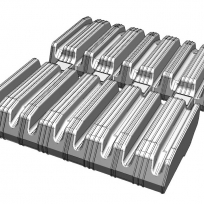

Terrapin Skid Steer Tracks

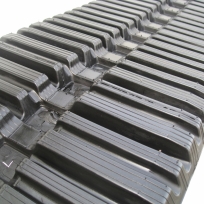

McLaren Industries' Terrapin series is our most versatile option for skid steer rubber tracks. The unique tread pattern balances comfort, performance, and longevity. Our Terrapin skid steer tracks deliver excellent traction and an incredibly smooth ride. Our Terrapin tracks are turf-friendly and ideal for working in environments like golf courses or backyards.

The unique trade pattern prevents rocks and other debris from damaging the rubber track body and internal structure. The Terrapin Rubber Tracks contain more traction than the common C-Pattern in 80% of applications.

Our Terrapin rubber tracks are also offered in Non-Marking Grey. These skid loader tracks eliminate black marks on sidewalks and driveways, saving you time and money from extra clean-up.

NextGen™ Rubber Tracks

McLaren NextGenTM Rubber Tracks are built to OEM specifications and quality. McLaren NextGenTM Rubber Tracks in all aspects are significantly better than all other skid steer rubber tracks sold on aftermarket.

- NextGen Technology Design Formulation (TDF™) skid steer rubber tracks are specifically for CLT use. NexGen TDF design performs better than standard OEM Block and C-Pattern rubber tracks. This pattern offers superior traction, a smoother ride, and improved durability in rocky conditions over OEM Block and C-Pattern skid steer tracks.

- NextGen TDF Super Series Rubber CTL replacement CTL tracks have the same great performance and advantages as NextGen TDF but with 20% more rubber. Ideal for an extreme application.

- NextGen C- pattern skid steer tracks are an equal OEM replacement in both durability and quality. Premium rubber compound and raw materials as used in OEM production skid steer tracks.

- NextGen Block pattern skid steer rubber tracks are an equal OEM replacement in both durability and quality, made with premium rubber compound and raw materials as used in OEM production rubber tracks.

- NextGen Zig-Zag rubber CTL replacement tracks provide excellent traction in mud, making them the best option for slippery terrain. Produced to OEM durability and quality standards, not your typical Zig-Zag track.

- NextGen Turf™ pattern CTL rubber skid steer tracks, a series we've designed specifically for landscaping applications, offer a smoother tread and lower ground pressure for working in sensitive environments. Protects grass better than any rubber tracks in the industry.

Maximizer™ Skid Steer Rubber Tracks

The Maximizer series is our value-priced line of replacement skid steer tracks. Reinforced steel belting delivers overall integrity and a long service life. Choose Maximizer if you want superior reliability with your skid loader tracks at an accessible price point. By far the best rubber track value in the industry.

Request a quote for skid steer tracks or call us at (800) 836-0040 for help choosing the best product for your needs. We'd be happy to recommend the best skid steer rubber tracks for your budget.

Click on the product movie to see the newest Terrapin multi-purpose CTL tread pattern developed by McLaren:

Video

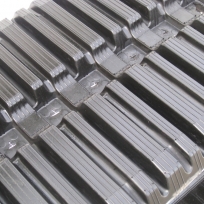

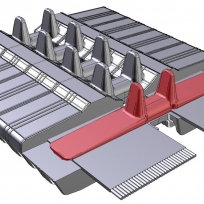

NextGen TDF™ rubber tracks are developed specifically for track loaders. Unlike excavator style tracks that are resized to fit track loaders, NextGen TDF track loader tracks are designed to handle the work-load and abuse of the most powerful track loaders.

- Longer life

- More heavy duty

- McLaren's rubber compound formula extends track service lifespan by as much as 70%

- McLaren's proprietary SpoolRite Belting™ continuous (jointless) belt system radically increases the tensile strength of NextGen TDF's internal structure

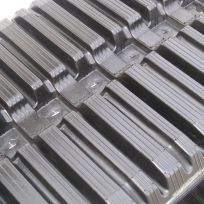

- TDF has multiple lugs per pitch profile

- Designed to carry the full load of the machine at maximum engine capacity

From 320 to 450 mm wide tracks.

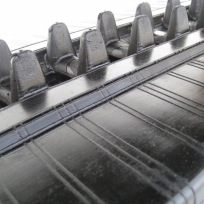

SpoolRite Belting Technology: a single jointless non-overlapping continuous steel belt. This technology consists of one single continuous steel cable with no joint connection and thus with no weak point prone to track brake. Specifically developed for track loaders, McLaren's SpoolRite™ belting technology provides the industry's strongest track structure.

NextGen TDF is a high performance Series of rubber tracks for the most demanding users of compact track loaders. This OEM approved rubber track is our recommendation for all customers looking for high quality replacement rubber track and increased overall productivity.

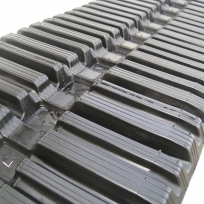

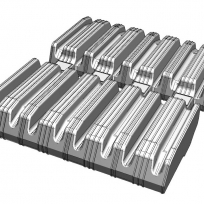

TDF multiple lugs per pitch profile together with double offset tread pattern minimize vibration and help deliver a smoother ride. TDF’s innovative tread pattern protects the track body and effectively stops the growth of cuts and cracks

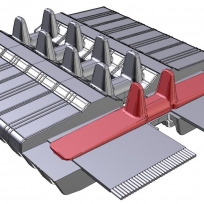

The NextGen TDF rubber track uses CCQS™ (Crack and Cut Quarantine System), a series of narrowly spaced lug-bars that contain the growth of any accidental cut or crack. By preventing the spread of the surface damage, CCQS contributes noticeably for a longer service life.

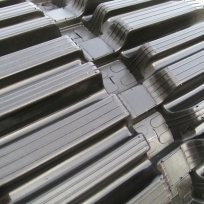

NextGen TDF™ Super Series rubber tracks are developed specifically for track loaders doing extra heavy duty work. Unlike excavator style tracks that are resized to fit track loaders, NextGen TDF Super Series track loader tracks are designed to handle the work-load and abuse of the most powerful track loaders.

- With 20% MORE RUBBER

- Longer life

- More heavy duty

- McLaren's rubber compound formula extends track service lifespan by as much as 70%

- McLaren's proprietary SpoolRite Belting™ continuous (jointless) belt system radically increases the tensile strength of NextGen TDF's internal structure

- TDF Super Series has multiple lugs per pitch profile

- Designed to carry the full load of the machine at maximum engine capacity

From 320 to 450 mm wide tracks.

SpoolRite Belting Technology: a single jointless non-overlapping continuous steel belt. This technology consists of one single continuous steel cable with no joint connection and thus with no weak point prone to track brake. Specifically developed for track loaders, McLaren's SpoolRite™ belting technology provides the industry's strongest track structure.

NextGen TDF is a high performance Series of rubber tracks for the most demanding users of compact track loaders. This OEM approved rubber track is our recommendation for all customers looking for high quality replacement rubber track and increased overall productivity.

TDF multiple lugs per pitch profile together with double offset tread pattern minimize vibration and help deliver a smoother ride. TDF’s innovative tread pattern protects the track body and effectively stops the growth of cuts and cracks

The NextGen TDF rubber track uses CCQS™ (Crack and Cut Quarantine System), a series of narrowly spaced lug-bars that contain the growth of any accidental cut or crack. By preventing the spread of the surface damage, CCQS contributes noticeably for a longer service life.

Next Generation Series is McLaren's original premium quality rubber track line preferred by many OEMs. Superior-built, these tracks outperform other premium tracks on OEM tests. NEXT GEN C Pattern track is a classic pattern OEM quality track built with premium materials to match or surpass your original OEM track.

McLaren rubber tracks for compact track loaders stand out with consistent quality and flawless performance even on the harshest terrain. Main features and product advantages:

- SpoolRite Belting Technology

- Wear resistant rubber compound

- Reliable metal to rubber bonding

- Various tread patterns and short-pitch technology

NextGen rubber tracks outperform other premium tracks on OEM tests. Choosing premium rubber tracks by McLaren is a guarantee for increased productivity and longer undercarriage work life for your machine. A tread pattern for every size has been carefully selected and optimized to deliver the optimal traction and minimum vibrations for every machine range.

From 320 and 450 mm wide tracks.

SpoolRite Belting Technology: a single jointless non-overlapping continuous steel belt. This technology consists of one single continuous steel cable with no joint connection and thus with no weak point prone to track brake.

NextGen is a high performance Series of rubber tracks that guarantee more value for your money than any other aftermarket rubber track.

Next Generation Series is McLaren's original premium quality rubber track line preferred by many OEMs. Superior-built, these tracks outperform other premium tracks on OEM tests.

McLaren rubber tracks for compact track loaders stand out with consistent quality and flawless performance even on the harshest terrain.

NextGen Block Pattern track is a classic pattern OEM quality track built with premium materials to match or surpass your original OEM track.

- Reliability: Premium quality OEM approved rubber track

- Integrity: SpoolRite Belting Technology consisting of a single jointless steel belt

- Durability: Highest quality rubber compound developed by McLaren

Next Generation rubber tracks are the tracks that established McLaren as a leading rubber track manufacturer in the USA and abroad. Choosing premium rubber tracks by McLaren is a guarantee for increased productivity and longer undercarriage work life for your machine.

450 mm wide tracks.

Next Generation Series is McLaren's original premium quality rubber track line preferred by many OEMs. Superior-built, these tracks outperform other premium tracks on OEM tests. NextGen ZigZag pattern track is a OEM performance pattern track built with premium materials to match or surpass your original OEM track. It is designed specifically for slippery terrains with a tread pattern that delivers excellent wet traction in mud. Not recommended for rocky terrains.

McLaren rubber tracks for compact track loaders stand out with consistent quality and flawless performance even on the harshest terrain. Main features and product advantages:

- SpoolRite Belting Technology

- Wear resistant rubber compound

- Reliable metal to rubber bonding

- Various tread patterns and short-pitch technology

NextGen rubber tracks outperform other premium tracks on OEM tests. Choosing premium rubber tracks by McLaren is a guarantee for increased productivity and longer undercarriage work life for your machine. A tread pattern for every size has been carefully selected and optimized to deliver the optimal traction and minimum vibrations for every machine range.

320 and 450 mm wide tracks.

SpoolRite Belting Technology: a single jointless non-overlapping continuous steel belt. This technology consists of one single continuous steel cable with no joint connection and thus with no weak point prone to track brake.

NextGen is a high performance Series of rubber tracks that guarantee more value for your money than any other aftermarket rubber track.

The NextGen Turf series of rubber tracks are specifically developed for landscaping professionals who demand a smooth tread and reduced ground pressure. NextGen Turf rubber tracks leave a much lighter footprint than conventional tracks and reduce damage on delicate turf areas and various irrigation systems deployed underneath the delicate surface.

- Turf Protection - perfect for applications on golf courses, parks, and any landscaping work that requires turf protection

- Reduced Ground Pressure - specifically for landscaping professionals who demand a smooth tread and reduced ground pressure

- Lighter Footprint - much lighter footprint than conventional tracks which reduces damage on delicate turf areas and various irrigation systems deployed underneath the delicate surface

- Non-Marking Option - also available in our new orange non-marking rubber compound

450mm wide tracks

SpoolRite Belting Technology: a single jointless non-overlapping continuous steel belt. This technology consists of one single continuous steel cable with no joint connection and thus with no weak point prone to track brake. Specifically developed for track loaders, McLaren's SpoolRite™ belting technology provides the industry's strongest track structure.

NextGen TURF is a high performance Series of rubber tracks that guarantee more value for your money than any other aftermarket rubber track.

Specifically designed to prevent sensitive areas from damage, the McLaren non-marking rubber tracks are the solution for our most demanding customers.

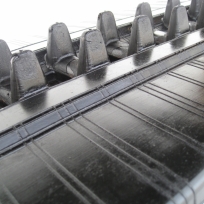

Cost effective aftermarket rubber tracks: the Maximizer rubber tracks for compact track loaders provide reliability at the right cost.

- Track integrity due to the continuous reinforced steel belt

- Lower priced to fit the needs of contractors with budget restrictions

McLaren’s compact loaders rubber tracks use not only high quality rubber compound but also up to 30% more rubber compared to alternative tracks from the same class to ensure you get the maximum rubber track life for your money.

From 180 to 450 mm wide tracks.

Maximizer Series of replacement rubber tracks for track loaders offer reliable quality at the lowest possible price. These rubber tracks are built with a cost effective rubber compound and reinforced continuous steel belt to ensure rubber track integrity and durability.

.jpg)