Maintaining Your Skid Steer Hydraulic System for Optimal Attachment Performance

If you’re looking to use your skid steer for operating attachments, its hydraulic system is one of the most important components to pay attention to. Designed to provide your equipment with optimal power for heavy-duty applications, these hydraulic setups are what make using attachments so effective. They also ensure you get the very most of each minute on the jobsite. As such, you’ll need to maintain the hydraulic system just as you would any other skid steer component. Here is what you need to know about maintaining your skid steer hydraulic system for optimal attachment performance.

The Importance of Maintaining Hydraulics

Before we can get into the basics of hydraulic maintenance, it’s crucial to understand why these steps are so important. While your skid steer’s hydraulic system is where your machine derives most of its power, even these parts can experience wear and tear over time. When this happens, there is potential for this system to break down when you need it most or fail to provide sufficient power for your attachments.

A well-maintained hydraulic setup promotes optimal hydraulic fluid quality and flow, maximizing the amount of pressure in the cylinder when producing power. It also keeps cylinders and motors moving correctly to provide optimal power to the machine and attachment. Even if you think your current system doesn’t need the extra attention, it’s always beneficial to double-check.

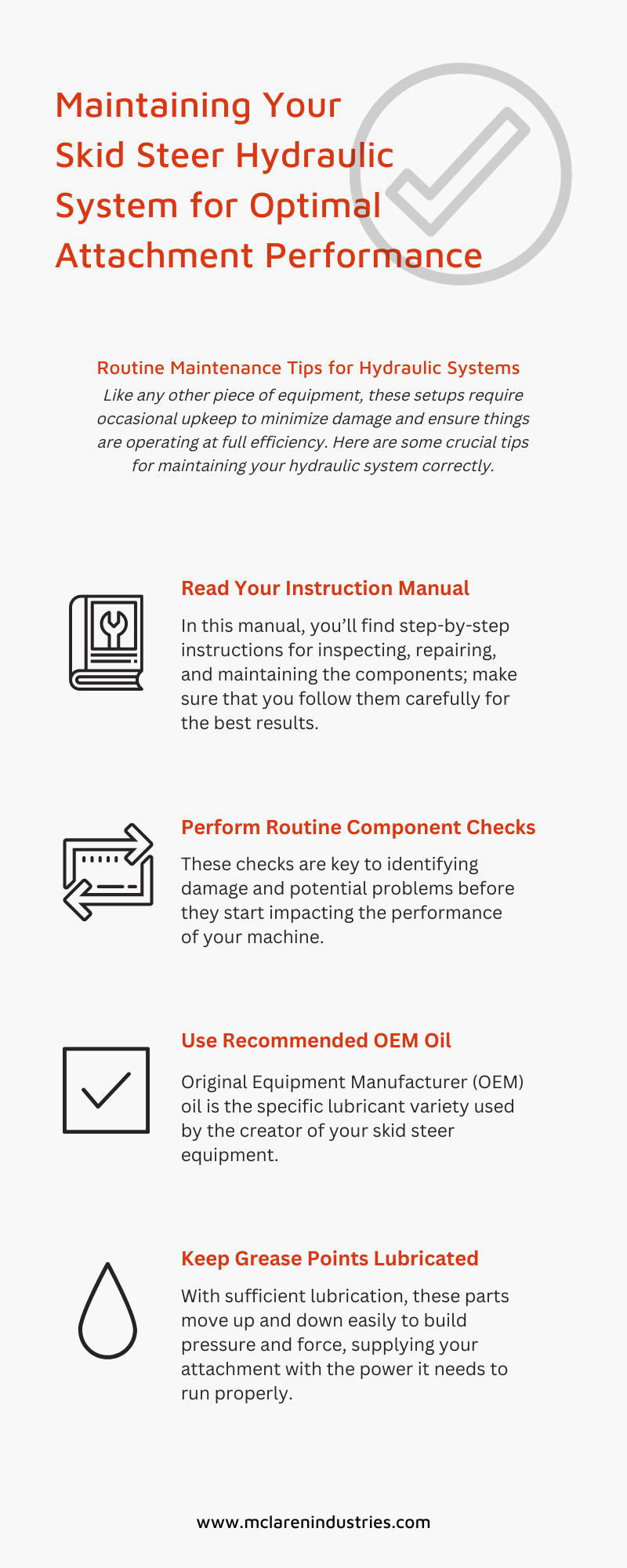

Routine Maintenance Tips for Hydraulic Systems

When it comes to maintaining your skid steer hydraulic system for optimal performance, there are several key factors to keep in mind. Like any other piece of equipment, these setups require occasional upkeep to minimize damage and ensure things are operating at full efficiency. Here are some crucial tips for maintaining your hydraulic system correctly.

Read Your Instruction Manual

First and foremost, you’ll want to check your skid steer’s manufacturing guide. Every piece of equipment comes with a booklet detailing the product, its features, and how to maintain it over time. As such, it’s crucial that you use this resource to educate yourself on the maintenance needs of your hydraulic system. In this manual, you’ll find step-by-step instructions for inspecting, repairing, and maintaining the components; make sure that you follow them carefully for the best results.

Perform Routine Component Checks

It’s essential to create a timeline for regular hydraulic component inspections. These checks are key to identifying damage and potential problems before they start impacting the performance of your machine. Because of this, you’ll want to perform daily, weekly, and monthly checks of various hydraulic components to ensure everything is in working order. Your instruction manual will detail which parts need revisiting and how often you should take a look at them.

Use Recommended OEM Oil

Original Equipment Manufacturer (OEM) oil is the specific lubricant variety used by the creator of your skid steer equipment. It’s the type of oil best suited for your machine and allows your skid steer’s hydraulics to perform at their very best. As such, we highly recommend using the correct OEM oil when maintaining your hydraulic system. This way, you know you’re using something compatible with your machine’s build.

Keep Grease Points Lubricated

Additionally, make sure you keep grease points lubricated at all times. These components include any moving bolts as well as the hydraulic pistons that help generate power. With sufficient lubrication, these parts move up and down easily to build pressure and force, supplying your attachment with the power it needs to run properly.

Best Operating Practices for Hydraulic Systems

Along with properly maintaining your skid steer’s hydraulic system, you also want to make sure you’re operating it carefully. Thoughtful operation of these machines can reduce the amount of strain you put on the system, helping to decrease long-term damage. This way, you’re less likely to experience excessively worn or malfunctioning parts. These are some best operating practices to know.

Use Only Compatible Attachment Products

Not all skid steer attachments are compatible with your particular type of skid steer. In fact, using a product with the wrong flow and weight requirements can lead to premature damage and poor attachment operation. For this reason, it’s important to double-check component compatibility before you commit to buying a specific attachment. As you shop, check the amount of hydraulic flow each model needs and compare it to what your skid steer can provide.

Ensure Proper Attachment Connection

It’s also important to connect your skid steer and its attachment properly; correct alignment facilitates the best possible flow between your hydraulic system and the attachment product. As such, it’s this aspect of operation that encourages the highest amount of power transfer and maximizes the product’s capabilities. You should always double-check everything is attached as required and that you have optimal control over the machine.

Don't Exceed Machine Output

Every skid steer hydraulic system has a maximum power output, and exceeding that amount can cause damage to critical components. Because of this, you’ll want to operate your machine with care and monitor how hard you’re pushing the device. Leaving your system running for too long can eventually cause it to overheat and fail, much like the engine of a car. Therefore, you’ll want to use your attachments at designated intervals and give your skid steer plenty of time to cool down between tasks.

Clean Auxiliary Hydraulic Fittings Before Connecting

As you use your skid steer equipment, you’ll notice that the hydraulic fittings along essential tubing gather residue. This is a normal part of using your hydraulic system; however, if left unmanaged, it can hinder the machine’s performance. You’ll want to develop the habit of cleaning these connections off before attaching a new product to ensure everything is ready for optimal use.

Understanding how to maintain your skid steer’s hydraulic system is a critical part of keeping your equipment and its attachments working properly. If you’re unsure where to start, consider reaching out to McLaren Industries. We always make sure our customers have a clear understanding of each product’s hydraulic needs, whether it’s our brush hogs or high-performing skid steer trencher attachments, and can help you find the right match for your skid steer. We can also provide advice for ensuring these parts stay in premium shape. Reach out to us here or give us a call at 800-836-0040 with any questions.

By McLaren Industries

By McLaren Industries